Micro-concrete for decorative floors and walls

|

Masters micro-concrete (also called Masters Beton Cire) is an ideal product for renovation and resurfacing. It doesn't require to remove old coatings, even on tiles on account of it excellent grip on all new and old supports. It is applied in two layers with only 2mm thickness. Interiors, exteriors and facades are beautifully rendered achieving decorative finishes. It can be applied to areas of any size both large and small without the need of any joints, to floors, walls , shelves and kitchen tops, sinks and bathtubs. Mechanical and physical characteristicsCoverage : About 1kg for 1 sqm for one coat |

How to use ?

1. Preparing surfaces

The surface must be resistant, clean, hard without cracks. Remove all dust and other substances of old coating who could damage the grip of the product (paint, oil, grease, fluorescence, GLU, sealers ... etc)

If you have some little cracks, you can repair it with an Epoxy Resin and insert a fiber mesh into this primer.

For an application on an old ceramics or tiles, a light sanding may be necessary to promote the adherence.

When your surface is ready, apply an adapted Primer.

You should use Masters Prim for porous surfaces or Masters Prim Plus for closed surfaces like paints, tiles or others waterproofs materials.

2. Application

The two components must be measured with precision. Use a measuring cup for the liquid and a scale for the powder. Prepare for instance, 3kg of powder (bucket) and 700ml of liquid resin. Mix mechanically in slow speed Masters micro-top concrete until obtaining of homogeneous mix.

Begin to apply the mixture in fine layer (about 1mm) with the trowel without trying to make directly perfect surface.

Apply regularly on the whole surface to be treated without interruption.

Let dry this primary layer during 4 at 6 hours.

Apply the second layer according the same method.

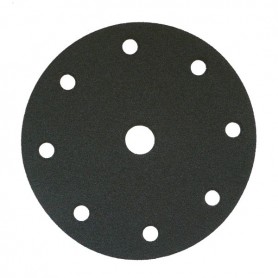

This time, press stronger on your trowel to insert the product into the first layer. This step is important to reduce the grain and create a smooth surface. Once the second layer ended, let it dry at least 48 hours before of sanding with grain of 120. For a better sanding, prefer a silicon carbide disc.

3. Protection

Apply two coats of sealer and prefer a bi-component sealer (polyurethane or epoxy) according to the use of the place.

- Formar

- Polvo + Carpeta

- Composición

- Cemento Portland y arenas de sílice + ligante a base de polímeros acrílicos

- Cobertura

- 1 kg por 1 m 2 para una capa

- COV

- Libre de COV: de acuerdo con la Directiva Europea 2004/42 / CE

- Color

- Disponible en 36 colores. Color personalizado bajo demanda

- Vida útil

- 1 año

- Granulometria

- 0,3 a 0,4 mm

- Densidad

- 2,1

- Resistencia a la compresión

- 7 a 12 Mpa (después de 2 días) / 30 a 35 Mpa (después de 28 días)

- Resistencia a la flexión

- 3 a 5 Mpa (después de 2 días) / 11 a 12 Mpa (después de 28 días)